Project Description – Makita Procenter

Material chosen – Metal, Wire, Acrylic, ABS, HIPS, Coroplast, Lens, LED lighting and UL certified power supply.

Features –

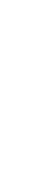

- Back grid panel system to display various tools with unlimited space utilize;

- Pop-out lit header to enhance brand;

- Changeable feature panels to promote the brand;

- Add-on base cabinet with diamond surface to stock product accessories as an option.

etc.

Challenge & Solution –

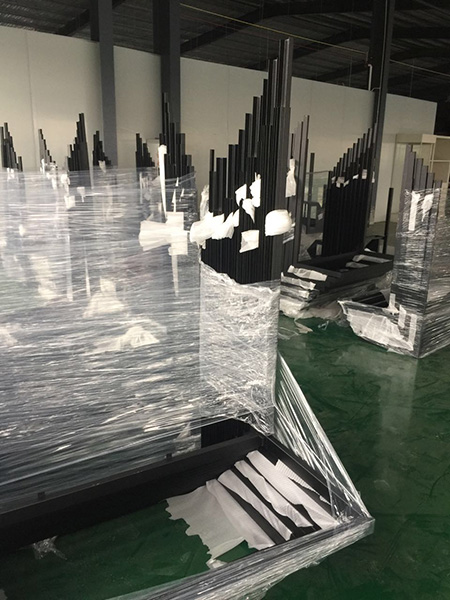

- Challenge: Knock down version to save ocean freight and easy to set up.

Solution: K/D version: Base + upper assembly+ grid wall + lit header + coroplast

- Challenge: Lightversion for easy handling

Solution: ABS V/F lit header, grid wall, coroplast silk screened same color with powder coating metal to keep harmonious visual.

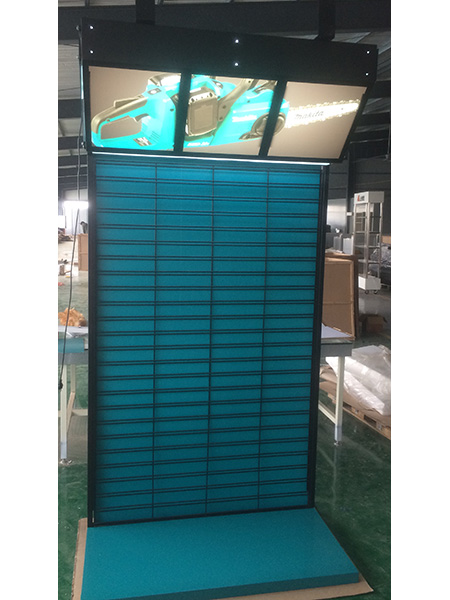

- Challenge: changeable feature panels

Solution: “Z” channel graphic retainer with one end opening/wing screw fixed to slide in high quality digital printing PET lens; Back/Top header cover is flexible to hold inside, be accessed from top window to replace graphic at front window.

- Challenge: Changeable LED light, to replace new one when the light gets dark after years. No need to replace whoe display;

Solution: Use LED light tube to snap into stainless spring clip.

etc.

Customer Feedback –

The display is really amazing! It’s out of our expectation!

Related photos

If you want to know more about us, Please don’t hesitate to Contact us

.jpg)