Where to Wholesale Labubu Display Case for Your Toy Store

If you run a toy store or online collectible shop, finding a reliable Labubu display case wholesale supplier can make a big difference in how your products look and sell. The right display case not only protects your figures but also elevates your store’s image — especially when dealing with collector favorites like Labubu figures.

Why Toy Stores Need Labubu Display Cases

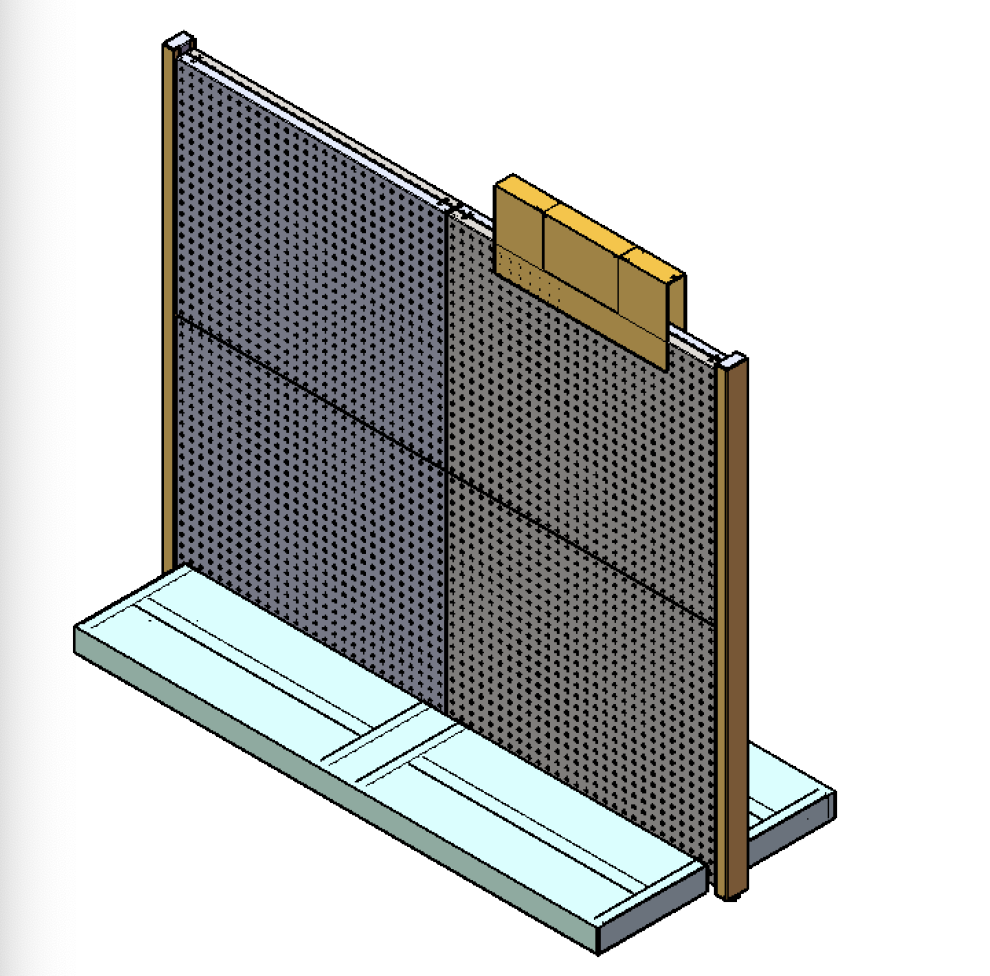

Collectors today are more discerning than ever. A premium acrylic Labubu display case gives your store a professional edge, helping you display limited-edition figures neatly and dust-free. For toy retailers, offering high-quality display boxes can even become an upsell product for customers who want to protect their Labubu collections at home.

Where to Source Labubu Display Case Wholesale

There are several ways to wholesale Labubu display cases effectively:

- Direct Manufacturer Partnerships: Working with a dedicated toy display case supplier ensures you can customize sizes, materials, and packaging.

- Online Wholesale Platforms: Websites like Alibaba or specialized acrylic display manufacturers offer ready-to-ship bulk options.

- Local Distributors: Partnering with regional distributors can shorten lead times and lower logistics costs.

If your toy business needs customization—such as engraving or logo printing—contacting a Labubu display case factory directly gives you the most control over design and quality.

Key Features to Look For

When choosing a display supplier, focus on:

- Material Quality: Opt for thick, crystal-clear acrylic.

- Customization Options: Adjustable layers or LED lighting add appeal.

- Bulk Pricing: Check minimum order quantities and tiered discounts.

By focusing on these aspects, your Labubu acrylic box display range can cater to both high-end collectors and mass retail.

Why Choose Impressive Display

At Impressive Display, we specialize in custom acrylic display solutions for pop culture brands and toy retailers. Our Labubu display case wholesale service helps you order in bulk with confidence—quality, packaging, and design tailored to your brand needs.

FAQ About Labubu Display Case Wholesale

1. Where can I wholesale Labubu display cases for my toy store?

You can source Labubu display cases directly from acrylic display manufacturers or verified suppliers like Impressive Display. They offer bulk pricing, customization, and reliable shipping for retailers worldwide.

2. Can I customize the Labubu display case for my brand?

Yes, most manufacturers allow full customization, including logo printing, adjustable layers, LED lighting, and packaging design, ensuring the Labubu display box aligns with your store branding.

3. What materials are best for Labubu display boxes?

The best Labubu display cases are made from premium transparent acrylic, known for its clarity, durability, and dust resistance. This material offers both protection and high-end presentation for collectible figures.